Gauge sizing is a standardized measurement system used to determine the thickness or diameter of materials like wires‚ metals‚ and fabrics․ It ensures consistency and accuracy across industries‚ helping maintain quality and reliability in manufacturing and construction․ Understanding gauge sizing is crucial for selecting the right materials and tools for specific applications․

What is Gauge Sizing?

Gauge sizing is a standardized system for measuring the thickness or diameter of materials like wires‚ metals‚ and fabrics․ It provides a consistent way to classify materials‚ ensuring compatibility and quality across industries․ Gauge systems vary by material type‚ with examples including the American Wire Gauge (AWG) for wires and sheet metal gauges for thickness․ Accurate gauge sizing is critical for manufacturing‚ construction‚ and engineering to maintain structural integrity and performance standards․

Importance of Accurate Gauge Sizing

Accurate gauge sizing is essential for ensuring the quality‚ safety‚ and reliability of materials in various industries․ It prevents material failures‚ reduces waste‚ and optimizes production processes․ Proper sizing ensures compliance with industry standards‚ avoiding costly rework and enhancing product performance․ In manufacturing‚ precise gauges are critical for maintaining structural integrity and meeting customer specifications․ Accurate measurements also improve efficiency and consistency‚ making it a cornerstone of successful engineering and production practices across sectors․

Common Applications of Gauge Sizing

Gauge sizing is widely used in manufacturing‚ construction‚ and engineering to measure materials like wires‚ metals‚ and plastics․ It ensures proper fit and functionality in machinery‚ electronics‚ and structural components․ In textiles‚ gauge sizing determines fabric thickness for knitting and sewing․ Aerospace and automotive industries rely on precise gauges for safety-critical parts․ Accurate sizing is also essential in medical devices‚ ensuring reliability and performance․ Its applications span across industries‚ emphasizing the need for consistency and precision in material measurement․

Understanding Gauge Sizing Basics

Gauge sizing is a standardized system for measuring material thickness or diameter‚ ensuring consistency and accuracy․ It involves key concepts like measurement techniques‚ tolerance standards‚ and material-specific applications‚ providing a foundation for precise material selection and quality control across various industries․

Key Concepts in Gauge Measurement

Gauge measurement involves understanding calibration‚ precision tools‚ and material properties․ Calibration ensures accuracy‚ while tools like micrometers and calipers provide reliable data․ Tolerances define acceptable measurement ranges‚ and material thickness or diameter must align with specific standards․ Consistency is achieved by following standardized procedures‚ and documentation ensures traceability․ Proper training and expertise are essential for accurate readings․ Regular maintenance of tools and adherence to industry standards further enhance measurement reliability and consistency across applications․

Gauge Numbering Systems Explained

Gauge numbering systems are standardized methods for measuring material thickness or diameter․ Systems like American Wire Gauge (AWG) and sheet metal gauge use inverse scales‚ where higher numbers indicate thinner materials․ These systems vary by industry and material type‚ ensuring consistency in production․ For example‚ wire gauges are logarithmic‚ while sheet metal gauges are based on weight per area․ Understanding these systems is crucial for accurate material selection and specification across engineering and manufacturing applications․

Material Thickness and Gauge Relationship

Gauge sizing directly relates to material thickness‚ with specific numbers corresponding to precise measurements․ In systems like the American Wire Gauge (AWG)‚ a higher gauge number indicates a thinner material․ Similarly‚ sheet metal gauges use a standardized scale to define thickness․ This relationship ensures consistency across industries‚ allowing for accurate material specification․ Understanding this correlation is essential for selecting the right materials for engineering‚ manufacturing‚ and construction applications‚ ensuring quality and reliability in final products․

Tolerances and Standards in Gauge Sizing

Tolerances and standards in gauge sizing ensure accuracy and consistency across materials and industries․ Organizations like ASTM and ISO establish specific guidelines for allowable variations in thickness or diameter․ These standards help manufacturers meet quality requirements and prevent deviations that could lead to material failure․ Adhering to these tolerances is critical for maintaining reliability and interchangeability in engineered components‚ ensuring that materials perform as expected in their intended applications․

Types of Gauges

Types of gauges vary‚ including wire‚ sheet metal‚ knitting needle‚ and screw gauges․ Each serves specific purposes‚ ensuring precise measurements for materials like wires‚ metals‚ and fabrics․

Wire Gauge (AWG ─ American Wire Gauge)

The American Wire Gauge (AWG) system measures wire diameters‚ crucial for electrical applications․ It ranges from 0000 (thickest) to 40 (thinnest)․ Larger numbers indicate thinner wires․ AWG ensures safe current flow‚ durability‚ and conductivity‚ essential for wiring‚ circuits‚ and cables․ Proper gauge selection prevents overheating and ensures efficiency in electrical systems․ Understanding AWG is vital for engineers and electricians to maintain safety and performance in their work․ It’s a cornerstone in electrical engineering and design․

Sheet Metal Gauge

Sheet metal gauge measures the thickness of metal sheets‚ with lower numbers indicating thicker materials․ Commonly used in manufacturing‚ construction‚ and automotive industries‚ it ensures compatibility and durability․ Factors like load-bearing requirements and corrosion resistance influence gauge selection․ Standards vary‚ but ASTM guidelines are widely followed․ Proper gauge selection is critical for structural integrity and longevity․ Using calipers or micrometers‚ professionals can accurately measure and verify sheet metal thickness to meet project specifications and safety standards effectively․

Knitting Needle Gauge

Knitting needle gauge refers to the measurement of needle size and stitch tension to ensure consistent fabric quality․ It involves counting stitches per inch to match pattern requirements․ Proper gauge ensures the finished product fits as intended․ Knitters use rulers or gauge measuring tools to check their work․ Achieving accurate gauge is crucial for garments‚ accessories‚ and textiles․ Swatching is a key step to verify gauge before starting a project‚ ensuring time and materials are used efficiently․ Consistent gauge guarantees professional-looking results every time․

Screw Gauge (Machinery’s Handbook)

A screw gauge measures screw thread dimensions‚ ensuring precision in machinery and manufacturing․ It verifies pitch diameter‚ thread angle‚ and depth․ The Machinery’s Handbook provides standards for screw gauge usage‚ detailing proper techniques and tolerances․ Screw gauges are essential for quality control‚ ensuring interchangeability of parts․ They typically consist of a threaded anvil and a measuring spindle․ Types include three-wire and best-fit gauges․ Accurate screw gauge measurement is critical for maintaining consistency in mechanical components and ensuring proper assembly and functionality․

How to Choose the Right Gauge Size

Selecting the correct gauge size involves considering material type‚ application requirements‚ and desired thickness․ Proper sizing ensures optimal performance‚ safety‚ and compatibility across various industrial and manufacturing applications․

Factors Affecting Gauge Size Selection

Several factors influence gauge size selection‚ including material type‚ application requirements‚ load-bearing capacity‚ environmental conditions‚ and industry standards․ Material thickness‚ durability needs‚ and flexibility also play a role․ Additionally‚ cost‚ availability‚ and manufacturer specifications are considered․ Understanding these factors ensures the chosen gauge meets performance‚ safety‚ and regulatory demands‚ optimizing functionality and reliability in various industries․

Steps to Determine the Correct Gauge

To determine the correct gauge‚ start by understanding the application requirements․ Measure the material’s thickness or diameter using calipers or micrometers․ Consult industry standards or conversion charts to match measurements with the appropriate gauge․ Consider factors like flexibility‚ durability‚ and load-bearing capacity․ Select a gauge that aligns with the intended use and manufacturer specifications․ Finally‚ verify the gauge with precision tools to ensure accuracy and compliance with quality standards․

Common Mistakes in Gauge Sizing

Common mistakes in gauge sizing include misusing measurement tools‚ neglecting calibration‚ and relying on incorrect conversion charts․ Many individuals overlook material flexibility‚ leading to inaccurate selections․ Others mistakenly assume all gauges are universal‚ ignoring industry-specific standards․ Overestimating or underestimating gauge sizes can result in structural weaknesses or wasted resources․ Proper training and adherence to guidelines are essential to avoid these errors and ensure precise‚ reliable sizing for optimal performance and safety․

Conversion Charts and Tables for Gauge Sizing

Conversion charts and tables are essential tools for gauge sizing‚ providing standardized measurements across different materials․ They offer precise equivalencies between various gauge systems‚ ensuring accuracy in selecting the right size․ These resources are particularly useful for comparing wire‚ metal‚ and fabric gauges‚ helping users avoid errors․ By referencing these charts‚ professionals can ensure consistency and compliance with industry standards‚ making them indispensable for precise material selection and optimal performance․

Gauge Sizing for Specific Materials

Gauge sizing varies across materials like steel‚ plastics‚ and textiles‚ each requiring tailored measurements․ This section explores material-specific gauges‚ ensuring precise sizing for optimal performance and durability․

Gauge Sizing for Steel and Metals

Steel and metal gauge sizing is critical for construction and manufacturing․ Thinner gauges indicate higher numbers‚ while thicker gauges have lower numbers․ Standards like ASTM and ISO regulate metal gauges‚ ensuring consistency․ For example‚ a 10-gauge steel is thicker than 12-gauge․ Accurate sizing ensures structural integrity‚ safety‚ and cost-efficiency in applications ranging from automotive to construction․ Proper measurement tools‚ such as calipers‚ are essential for precise assessments․ Material thickness directly impacts strength and durability․

Gauge Sizing for Plastics and Polymers

Gauge sizing for plastics and polymers ensures precise thickness measurements‚ crucial for applications like packaging‚ automotive‚ and medical devices․ Unlike metals‚ plastics are lighter and more flexible‚ requiring specific gauges tailored to their material properties․ Common methods include micrometers and laser thickness gauges․ Environmental factors like temperature and humidity can affect measurements‚ so controlled conditions are essential․ Accurate sizing ensures durability‚ consistency‚ and compliance with industry standards‚ making it vital for manufacturing high-quality plastic products․

Gauge Sizing for Fabric and Textiles

Gauge sizing in fabrics and textiles refers to measuring the density of stitches or threads per unit length‚ ensuring consistency in weave and knit patterns․ It is crucial for applications like knitting‚ sewing‚ and upholstery․ Fabric gauge determines durability‚ texture‚ and drape‚ with different materials requiring specific measurements․ Accurate sizing ensures proper fit‚ comfort‚ and aesthetic appeal in garments and textiles․ Tools like knitting gauges or specialized measuring devices are used to maintain precise standards‚ ensuring quality and reliability in fabric production․

Measurement Techniques

Measurement techniques involve using tools like calipers‚ microscopes‚ and digital gauges to accurately determine material thickness or diameter; These methods ensure precision and consistency in gauge sizing․

Using Calipers for Gauge Measurement

Calipers are essential tools for precise gauge measurement‚ offering accuracy in determining material thickness or diameter․ Digital‚ dial‚ and vernier calipers are commonly used‚ with digital models providing instant readings․ To ensure accuracy‚ calibrate the tool before use and measure multiple points for consistency․ Proper handling involves placing the material firmly between the jaws and avoiding uneven surfaces․ Regular maintenance‚ such as cleaning and recalibrating‚ extends the tool’s lifespan and reliability․ Always follow manufacturer guidelines for optimal performance and precise gauge sizing․

Microscope Measurement for Precise Gauges

Microscope measurement offers high precision for gauge sizing‚ particularly for tiny or intricate materials․ Optical and digital microscopes are commonly used‚ providing magnified views to assess thickness or diameter accurately․ This method is ideal for industries like aerospace and electronics‚ where exact measurements are critical․ Proper calibration‚ stable lighting‚ and skilled operation ensure reliable results․ Microscope measurement complements other tools like calipers‚ offering a detailed inspection for precise gauge sizing in specialized applications․

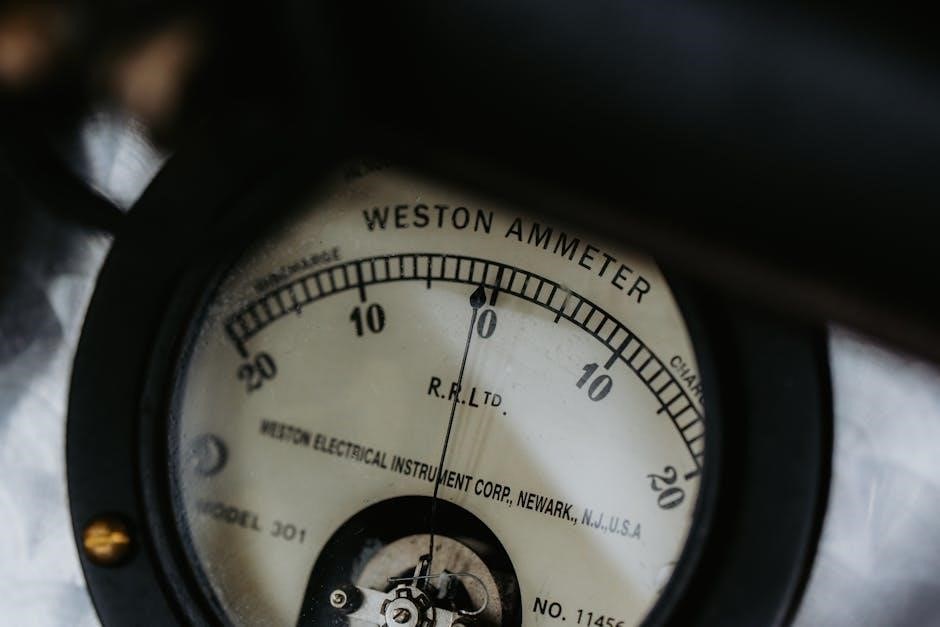

Digital vs․ Analog Gauge Measurement Tools

Digital and analog tools differ in gauge measurement accuracy and ease of use․ Digital gauges provide precise‚ instant readings with memory storage and data transfer options‚ making them ideal for high-precision tasks․ Analog tools offer simplicity and cost-effectiveness‚ relying on mechanical scales for measurements․ Both tools are widely used‚ with the choice depending on the application’s requirements‚ industry standards‚ and user preference․ Digital tools often enhance efficiency in modern manufacturing‚ while analog tools remain reliable for basic needs․

Troubleshooting Gauge Sizing Issues

Common gauge sizing issues include measurement errors‚ calibration problems‚ and material variability․ Solutions involve recalibrating tools‚ verifying standards‚ and ensuring proper training to maintain accuracy and consistency․

Common Problems in Gauge Sizing

Common issues in gauge sizing include inaccurate measurements‚ improper tool calibration‚ and material variability․ Human error‚ such as misreading gauges or using incorrect techniques‚ is prevalent․ Additionally‚ environmental factors like temperature changes can affect gauge accuracy․ Misaligned tools and worn-out equipment also contribute to inconsistent sizing․ Ensuring regular calibration‚ proper training‚ and adherence to standards can help mitigate these problems and improve overall measurement reliability across various industries․

Solutions for Inconsistent Gauge Measurements

To address inconsistent gauge measurements‚ ensure regular calibration and maintenance of tools․ Proper training on measurement techniques and adherence to industry standards is essential․ Using high-quality‚ precise gauges and documenting measurements can enhance accuracy․ Implementing statistical process control and environmental controls‚ such as temperature regulation‚ further reduces variability․ Regular audits and quality control checks help identify and correct issues promptly‚ ensuring reliable and consistent gauge sizing across operations․

Best Practices for Gauge Sizing

Regularly calibrate tools‚ train staff‚ and use high-quality gauges․ Document measurements and maintain consistent environmental conditions․ Adhere to industry standards for reliable and accurate sizing practices․

Calibration and Maintenance of Gauge Tools

Calibration and maintenance of gauge tools are crucial for ensuring accuracy and longevity․ Start by using certified standards to verify measurements․ Regularly clean tools to prevent contamination and store them in protective cases․ Environmental factors like temperature and humidity can affect precision‚ so control these variables․ Schedule periodic recalibrations and adhere to manufacturer guidelines to maintain reliability․ Proper care prevents inaccuracies that could lead to defects or safety issues․ Training staff on these procedures ensures consistency and compliance with industry standards․

Documentation and Record-Keeping

Accurate documentation and record-keeping are essential for traceability and compliance․ Maintain detailed logs of gauge measurements‚ including dates‚ reference standards‚ and operator details․ Use digital tools or spreadsheets to organize data‚ ensuring easy retrieval for audits․ Regularly update records to reflect recalibrations or tool replacements․ Clear documentation supports quality control by providing a historical record of measurements‚ helping identify trends and potential issues․ Consistent record-keeping also enhances accountability and streamlines reporting processes across teams and departments․

Training and Expertise in Gauge Sizing

Proper training and expertise are critical for accurate gauge sizing․ Operators should undergo workshops‚ certifications‚ and hands-on practice to master measurement techniques․ Regular updates on industry standards and tool advancements ensure proficiency․ Experienced professionals can mentor newcomers‚ fostering a culture of precision․ Continuous learning enhances understanding of complex materials and applications‚ ensuring reliable results․ Investing in training improves overall quality control and operational efficiency‚ reducing errors and promoting consistency across projects․

Tools and Equipment for Gauge Sizing

Essential tools include calipers‚ micrometers‚ and digital gauges‚ ensuring precise measurements․ These instruments vary by material type‚ such as wire or sheet metal‚ and application complexity․

Essential Tools for Accurate Gauge Measurement

- Calipers: Used for measuring thickness‚ diameter‚ and depth with precision․

- Micrometers: Provide highly accurate measurements for small dimensions․

- Digital Gauges: Offer quick and precise readings with minimal error margins․

- Gauge Blocks: Serve as reference standards for calibrating other tools․

- Dial Indicators: Measure surface finishes and small dimensional changes․

- Thickness Gauges: Specifically designed for materials like sheet metal or plastics․

- Optical Comparators: Use light and shadow for detailed inspections․

These tools ensure accuracy and reliability in various industrial applications․

Care and Maintenance of Gauge Measurement Tools

Proper care ensures the accuracy and longevity of gauge measurement tools․ Clean tools regularly with soft cloths and mild solvents‚ avoiding harsh chemicals․ Store them in protective cases to prevent damage․ Calibrate tools periodically according to manufacturer guidelines․ Handle tools with care to avoid scratches or misalignment․ Regularly inspect for wear and tear‚ replacing parts as needed․ Proper maintenance enhances precision and ensures reliable measurements across applications․

Industry Standards and Compliance

Industry standards like ASTM and ISO provide guidelines for gauge sizing‚ ensuring consistency and quality․ Compliance with these standards is crucial for meeting regulatory requirements across industries․

ASTM and ISO Standards for Gauge Sizing

ASTM and ISO standards provide detailed guidelines for gauge sizing‚ ensuring consistency and quality in measurements․ These standards outline specific tolerances‚ materials‚ and methodologies for accurate gauge sizing across industries․ Compliance with these standards is essential for manufacturers to meet regulatory requirements and maintain product reliability․ By adhering to ASTM and ISO guidelines‚ industries can ensure uniformity in gauge sizing‚ reducing errors and improving overall quality control․

Compliance Requirements Across Industries

Compliance requirements for gauge sizing vary across industries‚ with specific standards tailored to meet unique demands․ For instance‚ aerospace and automotive industries adhere to stringent gauge standards to ensure material reliability and safety․ In healthcare‚ precise gauge sizing is critical for medical devices․ Compliance ensures adherence to regulatory frameworks‚ avoiding legal and operational risks․ Industries like manufacturing and textiles also have specific gauge requirements‚ highlighting the importance of understanding and meeting these standards to maintain quality and safety across all sectors․

Future Trends in Gauge Sizing

Future trends in gauge sizing include advancements in digital measurement tools‚ automation‚ and AI integration for precision․ Sustainable materials and customizable gauges are expected to shape the industry․

Advancements in Digital Gauge Technology

Digital gauge technology is evolving rapidly‚ with AI-driven systems enhancing precision and automation․ Real-time monitoring and cloud connectivity enable data sharing and analysis․ These tools reduce human error‚ improve efficiency‚ and offer customizable solutions for various industries․ Advanced sensors and software integrate seamlessly‚ providing accurate measurements and streamlining processes․ Such innovations are revolutionizing gauge sizing‚ ensuring higher consistency and adaptability in modern manufacturing and production environments․

Sustainability and Material Innovation

Sustainability and material innovation are driving the development of eco-friendly gauge sizing solutions․ New materials like lightweight composites and recyclable alloys are being engineered to reduce environmental impact․ Gauge sizing plays a crucial role in ensuring these materials meet precise standards for strength and durability․ Innovations in recycling technologies and resource-efficient manufacturing processes are transforming industries‚ making gauge sizing a key tool in promoting sustainable practices and reducing waste․

Gauge sizing is fundamental to ensuring material quality and safety across industries․ Advancements in technology and sustainable practices continue to refine its applications globally․

Gauge sizing is a standardized system for measuring materials like wires‚ metals‚ and fabrics․ It ensures consistency‚ safety‚ and quality across industries․ Key points include understanding gauge numbering systems‚ tolerances‚ and material thickness relationships․ Accurate sizing is critical for performance and durability․ Tools like calipers and microscopes aid precise measurements․ Proper gauge selection prevents failures and ensures compliance with industry standards․ By mastering gauge sizing‚ professionals can optimize workflows and maintain high-quality outcomes in manufacturing and construction projects․

Final Thoughts on the Importance of Gauge Sizing

Gauge sizing is a fundamental aspect of ensuring precision‚ safety‚ and quality in various industries․ Accurate measurements prevent material failures‚ enhancing durability and performance․ Proper gauge sizing fosters compliance with industry standards‚ reducing risks and improving reliability․ By understanding and applying gauge sizing principles‚ professionals can optimize workflows‚ maintain consistency‚ and deliver high-quality outcomes․ Its importance cannot be overstated‚ as it directly impacts the success and longevity of products across manufacturing‚ construction‚ and beyond․